- Home

- Application

- Hydraulic Press

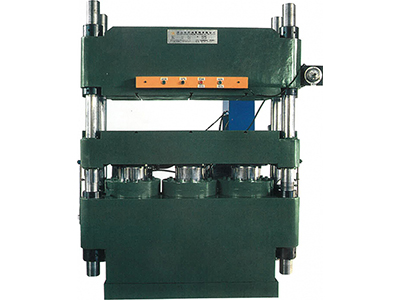

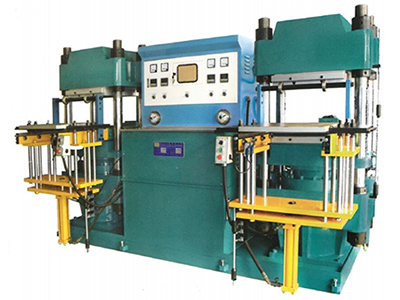

Hydraulic Press

For more than two decades, Hisun has customized a variety of hydraulic presses to meet unique customer requirements.

The clamp force on our hydraulic presses ranges between 50 to 3000 tons and offer a wide platen size range to fit different mold sizes. The largest platen we’ve ever made is 2.4m x 3.5, though larger sizes are available upon request.

Shown below are different hydraulic press applications. It is our pleasure to manufacture and customize different hydraulic presses to meet specific application needs.

-

Assembly

It doesn’t matter if you need a single hydraulic press or a full assembly line, we have the experience necessary to assist you.

Our hydraulic presses are suitable for a wide variety of assembly operations, including staking, crimping, broaching, notching, and inserting.

Our hydraulic presses are suitable for:

- Bushing / Bearing insertion

- Clamping

- Crimping

- Fastening

- Joining

- Punching / Blanking

- Riveting

- Track Pin Assembly

-

General Forming

Hisun has more than two decades of experience in the production of hydraulic forming presses, ensuring our presses provide precise guidance for customer molds.

We provide following forming solutions:

- Metal Forming

- Composite Forming

- Hot or Cold Forming

- Bending/Straightening

- Draw Forming

- Rubber Pad Forming

- Punching/Blanking

- Stamping/Coining

- Trimming

-

Powder Compaction

Hisun provides cost-effective powder compaction presses adaptable to different tools, including power handling, pick and place, and a variety of other equipment.

Whether users are using a traditional conventional powdered metal, chemical powder or polymers as the raw material, Hisun offers economical, turnkey solutions.

-

Hot and Cold

Hisun’s hydraulic presses uses hot and cold platens to complete a variety of processes, including molding, laminating, binding, and composites.

Our hydraulic presses are suitable for processing a variety of materials, including metal, alloy, fiber reinforced plastic, powder, composite material, rubber and more, with a customizable temperature of a maximum of 350 ℃ at maximum.

-

Forging

Hisun provides customized forging presses for a variety of open and closed die forging applications, including upsetting, cold heading, bending, impact extrusion, and more.

Our hydraulic presses provide a continuous pressure in stroke, making them ideal for a variety of forging applications.

Established in 1998, Dongguan Dalang Hisun Hydraulic Machinery Factory has more than 20 years of experience in the development and manufacturing of a variety of hydraulic equipment used in an equally extensive array of industries. We offer both standard and customized equipment, thus satisfying a variety of customer needs from around the world. Our customers come from the United States, Japan, Malaysia, Indonesia, Thailand, and other locations.

Established in 1998, Dongguan Dalang Hisun Hydraulic Machinery Factory has more than 20 years of experience in the development and manufacturing of a variety of hydraulic equipment used in an equally extensive array of industries. We offer both standard and customized equipment, thus satisfying a variety of customer needs from around the world. Our customers come from the United States, Japan, Malaysia, Indonesia, Thailand, and other locations.

-

Products

-

Application