- Home

- Products

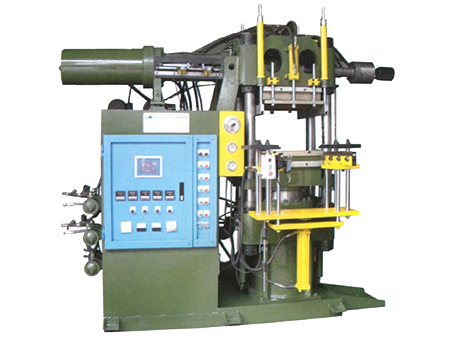

Hydraulic Equipment

For more than two decades, Hisun has been committed to the research, development, and manufacturing of hydraulic equipment including hydraulic presses, compression presses, injection molding machines and vacuum molding machines.

Not only do we provide standard hydraulic machines, but we also offer customization services to meet unique customer hydraulic machinery requirements.

Hisun provides hydraulic machines for the completion of a variety of cold and hot metal working processes including forming, bending, drawing, powder metallurgy, forging, stamping, blanking, and more. In addition, we also provide hydraulic machinery for the formation of non-metallic products, including thermoset plastics such as melamine resin and bakelite, rubber, wood, and more.

Our hydraulic machines use hydraulic oil as the transfer medium. This oil features an excellent lubrication performance and corrosion resistance. Any parts inside the machine that come into contact with each other are covered and coated in a layer of hydraulic oil, thereby ensuring the friction, vibration, and impact rates are reduced. This ensures our hydraulic equipment features a smooth driving performance, a high precision and a long service life.

- Capacity: 50-3000 ton

- Temperature: 350℃ at maximum

- Platen size: The largest platen size we’ve ever produced is 2.4m x 3.5m, though we offer larger if required.

It takes 60 days to complete production of customized hydraulic equipment with a 50 to 400 ton capacity. For custom made hydraulic equipment with a 500 to 4,000 ton capacity, the manufacturing period ranges between 75 to 180 days.

- The client must provide the primary product technical parameters, including mold structure, size, material, process requirements, and the required clamping force (we can calculate this for the customer if needed).

- Our engineer will then create a design drawing, including the exterior design and an action flow diagram.

- Both parties sign the contract once the design has been agreed upon, and the client pays a deposit.

- We begin production of the customized equipment.

Established in 1998, Dongguan Dalang Hisun Hydraulic Machinery Factory has more than 20 years of experience in the development and manufacturing of a variety of hydraulic equipment used in an equally extensive array of industries. We offer both standard and customized equipment, thus satisfying a variety of customer needs from around the world. Our customers come from the United States, Japan, Malaysia, Indonesia, Thailand, and other locations.

Established in 1998, Dongguan Dalang Hisun Hydraulic Machinery Factory has more than 20 years of experience in the development and manufacturing of a variety of hydraulic equipment used in an equally extensive array of industries. We offer both standard and customized equipment, thus satisfying a variety of customer needs from around the world. Our customers come from the United States, Japan, Malaysia, Indonesia, Thailand, and other locations.

-

Products

-

Application